PLA is sticky, it seems to stick to almost everything including Aluminium blocks and hot-ends, in an attempt to limit mess on my extruders I'm using a PTFE cooking liner cut to size.

This stuff is great, it's thin, very low cost (£1 / sheet) handles 260 Degrees C temperature and cuts easily.

You could use Silicon cooking sheet, but that tends to be thicker and rips, this stuff seems to work very well.

Cut out to wrap around the heater block.

Hold it all in place with a twist of copper wire (not Kapton tape as PLA and ABS sticks to that)

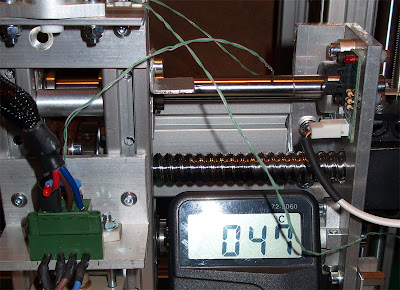

I'm using a Thermocouple down the inside of the heater barrel.

And even though my thermistor is perfectly calibrated it's location on the heater block reads higher than the actual temperature inside the heating barrel. To be expected, but something to remember especially using PLA.

To get a constant 195 Degrees C inside I need to run my heater block and thermistor control loop at 210 degrees C.

It's always worth trying to check and calibrate your set-up so you can know what temperature you are actually extruding at.

I will be connecting the Bowden cable and trying to print something later tonight, so hopefully I'll have some more updates tomorrow.

Rich

Curious, have you thought of or come across anybody who sprays the heating block and nozzle with PTFE spray? I'm currently looking for a way to make PLA like my Jhead a little less...

ReplyDeleteI think Makergear made some nozzles with PTFE coating (green I think) not sure how useful it was, I just tend to use a silicon wiper blade to clean the nozzle at the start of each print now.

Delete