A primary focus in on

the weight reduction of parts because of the foaming, but I was also

very interested in the ability to make both hard and foamed features

with just a single material.

At some

point you need to print more than test cubes, and for me the real

test was going to be complex objects that had a lot of islands, long

travel moves and a lot of start-stop retractions.

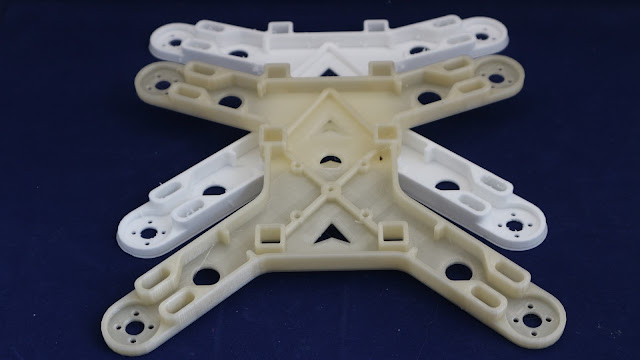

A good

test object is a quad-copter (drone) body (design by DV0001) – it needs to be light,

strong and has a lot of individual islands, large print area and

plenty of extruder retractions. To test my theory of extruder

retraction distance and high temperature, the above image shows an

early nozzle jam failure.

This model proved to be a perfect (difficult) test for the foaming material, if I had started printing with an easier model I would not have learned so much about the 'viable window of usage' and I bet I would have ended up having a lot more frustrating failures later on without understanding why I was seeing jamming etc.

This was also the first indication that a high flow rate flow rate, combined with higher temperature (giving a high expansion rate) and low layer height could be making nozzle jams more likely (when you also have long extruder retractions) - so I set out to discover what were bad combinations and what were better.

Nozzle Jam #2 – (Learning all the time...)

After a

tweak to the settings (see above in image), lower temperature(230

degrees C), increased layer height (0.25mm) and lower extruder

retraction (3.0mm) and a lower flow rate (50%) - The print made it

much longer into the print process, but still caused a nozzle jam before the

print was completed.

Print

success (No nozzle jams) –

Also don't be alarmed by the strings &

loops - I will explain why that's not a problem.

Critical

print success settings for me were –

Low extruder retraction (under

2.8mm) - I now use 2.6mm extruder retraction on all foaming prints.

225 Degrees C with a matched 45% flow rate

~44mm/sec Print speed on as many settings as possible (32mm/sec for small perimeters)

Higher layer

heights (0.25mm to 0.35mm) worked better for the foaming process

without causing nozzle jamming.

After I

decided on these settings, along with a print speed of around

44mm/sec and going no lower than 32mm/sec (apart from layer 1 –

that's also printed slightly cooler), I had no further problems at

all with nozzle jamming or print failures. Every other print from now on was a first time success.

Foamed

Benchy - Success!

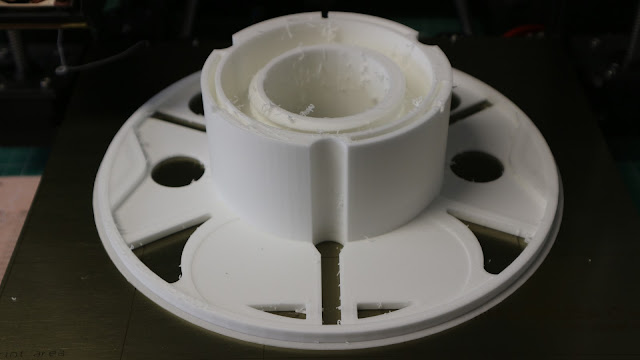

MasterSpool

Success ! (Again, don't worry about the ooze-hairs on

the print – they rub off)

Both the

drone body and a two part MasterSpool print are significant sized

object, with a lot of features, islands and travel moves.

You can

see some bumps and spots, but they just brush off. A little nozzle

ooze is the one aspect of this material that is going to be almost

impossible to eliminate, but in reality it does not seem to cause any

problems for the printed object or the final finish after a little

post processing.

A

little bit of clean up -

The

internal stringing 'hairs' and excess material looks to be a problem,

but it's surprisingly easy to remove with just your fingernail,

scraper or a blade. Removal does not leave missing areas of print or

significant blemishes on the printed part.

The drone model and MasterSpool prints had quite a few hairs due to travel moves and oozing. But they clear off the model really quickly, most with just a brush of your finger or finger nail.

|

| Straight off the printer, you are going to see some hairs and stringing, these are easily removed. |

Easy to see the 'hairs' on the Easter Egg model above - (Model designed by Jooxoe3i )

A light sanding will remove most surface imperfections and you won;t even be able to tell it's been sanded because it all feels the same as a very slightly textured surface. It's hard to describe, but I going to say that most people will really like the feel of the finish using this material.

At this point you may be thinking that you don't want to print at 'big 0.35mm layers', but the printed objects do not in any way look like models printed at 0.35mm layer heights...

You really need to see it in person to appreciate how nice a 0.35mm layer height can look on a model -

Very

impressive bonding of layers and to the naked eye a large layer

height like 0.35mm looks more like a printed object with 0.15mm

layers.

Weight

compare -

Above

shows the drone (quad-copter) body printed in both ColorFabb Natural

PLA/PHA and the LW-PLA foamed at 45% flow.

PLA/PHA

(Above left) @ 56.7g LW-PLA 45% flow (Above right) 26.3g

Both the

Benchy prints above were printed using LW-PLA – Left it's

non-foamed @205 Degrees C and Right it's foamed @225 Degrees C with a

45% material flow. Now a Benchy can actually float!

Significant

weight reduction for the MasterSpool – and it's completely

functional in it's lighter and foamed form.

1cm3

printed at '100%' but foamed @ 45% flow is around 0.6g

Bend,

twist and strength testing (Materials and laminates)-

For

some bend testing I printed a number of combinations of PLA/PHA

and various laminates of LW-PLA.

Simple

bend test setup shown below -

Bend Test results -

Clearly a

fully foamed print will have more bend and flexibility than a

normally solid print.

Compared

to the weight, the strength of a 45% flow foamed object is really

impressive.

Test D

laminate shows a lighter weight object with less bend than a solid

(Test B) object.

More strength and layer bond testing -

To test

layer bonding, some single wall 'vase' prints were used -

Single

perimeter 0.35mm layers printed with a 0.4mm nozzle

PLA/PHA

test snapped cleanly across a layer.

LW-PLA

(not foamed) also snapped across a layer, but required more force to

make it snap.

LW-PLA

(foamed) did not snap, but folded – it was not possible to break it

by hand across a layer line, instead it required tools to rip it

apart. The foamed print tends to tear in whatever direction stress is

being applied. Layer bonding strength is very good indeed.

I don't want to make it sound like it's the strongest thing ever, a foamed print will have some level of strength, and will be much more impact resistant You can throw it on the floor - a PLA part would break, and the foamed part will just dent and bounce off the floor) It also will have better layer bonding, but it's not a highly 'strong' material in it's foamed state, it's just really impressive indeed for it's weight. That said it's not easy to snap or break by hand either.

To get some idea of comparative strength, just try printing an object in PLA with flow set to 45% - it may just about print, but it will be incredibly weak and will most likely buckle, de-laminate and fall apart.

Doing the same with the LW-PLA at a foamed 45% flow rate produces a remarkably well layer bonded part with a surprising strength to weight ratio, it can be post processed and it looks great too.

Summary so far -

Okay, so I have done a lot more testing of flexibility, post processing, priming, sanding, destruction testing, printing lots of different models - so far used almost two complete 750g reels of the filament (remember that's like printing 2.5k to 3kg of parts).

Below images are just a little preview of what ill include in the next blog post for foaming PLA -

I'll save a lot more of of that for the next (Part 2) blog post on foamed printing, but I also want to give you some more advice and conclusions about using the material for the last few months.

My guidelines for successful use

of ColorFabb expanding PLA-

Don't use this material

on a bowden tube extruder system! - It's just does not work well.

A direct drive extruder

like the Prusa i3 MK2/3 or the Taz5/6 etc. is ideal.

If you are using a

glass or PEI print surface, I would strongly recommend using a

surface treatment – I tested glue stick, various sprays and

lacquers - then found that standard Magigoo for PLA worked the best

for me.

DO NOT adjust your flow rate by modifying the filament diameter or extrusion ratio in your slicing program, you should be using the following Gcode command in your starting script -

Examples - (Just use one of these at the end of your starting Gcode script) -

M221 S45 ; sets a 45 percent flow rate in the firmware for the ColorFabb Expand PLA

M221 S55 ; sets a 55 percent flow rate in the firmware for the ColorFabb Expand PLA

M221 S95 ; sets a 95 percent flow rate in the firmware for the ColorFabb Expand PLA

If you use the M221 command, you can then do nice things like set areas of your model to be printed solid (not foamed with 100% flow) and other parts to be foamed at 45% - You will not be able to do that if you mess about with the filament diameter of extrusion ratio.

All the testing /

tuning and experimentation below were done with a E3D V6 hot-end and

0.4mm nozzle. (I will be testing it out with other extrusion / hot-end systems too).

I intend to do some

further testing on the TAZ6 Moarstruder (Volcano 1.2mm Nozzle) if I

can get some of this filament in 2.85mm. I think the large nozzle and

a ~>2mm layer height may be possible and very interesting to see !

Make printing speeds

for different moves as similar as possible (where appropriate) –

basically try to avoid sudden changes in print speed / flow (other

than extruder retraction).

Do not chase a magical

value for extruder retraction – there is not a setting that will

eliminate ooze using this material – but you can minimise problems,

more importantly you need to tune the extruder reversal to avoid

chances of hot-end & nozzle jamming...

I can't stress how

important this next comment is – you WILL have an nozzle jam during

any significant testing and experimentation of this material. It's

not all that hard to clear a foamed blockage on an E3D V6, but it may

be more difficult on other machines / nozzles out there. You have

been warned!

Trigger point for

expansion 'puff-point' is dependent on print speed, temperature and

material flow percentage. - The instantaneous energy that's being

transferred into the material as it passes through the nozzle.

Extrusion volume, 'speed' and dwell in the nozzle plays a really big

part in getting a controlled expansion and repeatable material flow

for printing different types of objects.

In the past I have

experimented with printing PLA very fast indeed, it's not unusual to

bump up the extrusion temperature to 260+ Degrees C just to be able

to get enough thermal energy into the material at very rapid flow

rates.

When testing out the

Volcano and a Bondtech extruder on the Hangprinter with a 1.65mm

Nozzle the 1.75mm PLA feed needed to be well over 270 Degrees C –

just to get it melting and printing, and even that showed a slightly

matt finish, where the PLA being used would normally have been shiny.

You could slow things down but who wants to print big things slow :)

If however you let that

PLA material sit in the hot-end at that temperature during non extrusion events for too long it will quickly turn to the consistency

of honey and start to degrade and eventually burn.

The Expanding PLA can

handle very high temperatures quite well, but you also do have to

consider the energy, flow rate (deposition of material rate) and

thermal expansion rate of the filament carefully, so that means

tuning your slicing program so you get optimal conditions.

For a stock Prusa i3

MK2/3 I did not need to change any firmware settings, but did tune

Slic3r settings for more consistent results, especially with regards

to changes in print speed for different model features.

I found it best to

determine the ideal 'puff-point' with as consistent speed settings as

possible. This means smoothing out the changes in print acceleration,

for example inner and outer perimeter should be similar, infill and

even small islands need to be closer to all other printing speeds,

rather than very fast or very slow as you may have them when printing

PLA.

You can use fan cooling

– but only around half of 'normal' PLA settings. If you use more

cooling it will change the puff-point and limit expansion of the

material. You can even set cooling and extrusion temperatures to be

just a few degrees or percentage different per layer and see the

foaming form or not.

I used no fan for the

first layer and also a slightly lower extrusion temperature (222) to

compensate for a slower first layer speed.

Interestingly if you

print at around 195 to 205 Degrees C, this material will behave just

like 'normal' PLA. There is no real reason to do this unless you want

a more solid/hard feature in your expanded model or a multi-density

laminate like I tested above.

Trigger

points with hot-end jamming for me were -

Too much extruder

reversal – >2.8mm and it would jam every time at some point in a

'real life model' print where travel moves and island printing were

frequent.

I experimented to over

3.5mm extruder reversal – trying to eliminate ooze on travel moves,

but it just caused more problems (it's better to lower the

temperature to help combat oozing – see below).

If you pull the

semi-expanded filament back too far into the thermal break or

cool-zone it will jam.

Tune this to failure

mode and then back off – I have had 100% reliable printing of many

different types of objects after I lowered extruder reversal length

to 2.6mm for the V6 nozzle.

Every print would

always fail at over 3.0mm extruder reversal.

Generally the higher

heat you go, the more you will need to reduce the flow rate – if

you don't you will get very wide extrusion traces and that will be

much more likely to block the nozzle at some point during your print.

You will end up with a

combination of temperature, print speed and flow, that gives you a

'normal' extrusion width for your nozzle size, and then you can print

foamed objects with a similar accuracy and (often better) print quality than you get with

'normal' PLA.

Observations

for finish and post processing -

Don't worry about the

ooze / stringing / whiskers – they rub off easily and for whatever

reason you don't actually see any real defects in the finished model

– like missing sections of outlines or indents or bumps. You should

be 'loosing some volume' from your printed object, but due to the

foaming and general ability to blend layers together you don't see

these strings or bumps translate into lasting defects on the printed

model with just a little post processing clean-up.

Should

you try this material? -

Do you need light

weight printed objects?

As long as you are

prepared to tweak and tinker with the settings to tune temperature,

speed and flow with your specific 3D Printer, it is a really

interesting material that can give unique optical, mechanical and

weight related properties to 3D printed objects.

You can print 2 x as

many things with a 750g coil of filament...

You can actually print

parts out faster – even with slower print speeds... (Because you

can break the 'normal' slicing rules using the the same sized nozzle

- you can use a higher layer height and line width and even less

perimeters and infill for an object and it will still have well

bonded layers and a 'solid' finished form.

For me, once I had my

settings tuned in – I found I could print almost anything I would

print with regular PLA in the LW-PLA (Light weight expand PLA).

If you make lot of cosplay parts, props, models, buildings, prototypes and almost anything you would want to show off to a client (either with just a light sanding or full paint finish) I would say you have to at least try this material.

I have really enjoyed using it, and I find more uses for it every day - I can only hope one day ColorFabb decides to release #MasterSpool compatible refill coils of their filament, but if you can live with the fact it comes on a single use polycarbonate plastic spool... then I can strongly recommend trying out the material for 3D Printing.

Final

thoughts –

And a message to 3DP material manufacturers -

I'm excited about this,

not just the foaming filament, but the fact we are still seeing

research, development and advancements in filament's and materials

designed exclusively for the 3D printing process.

The other aspect is

that we need 3D printing filament (and resin) manufacturers to

actually release these materials to users. I say this because I have

tested many pre-release materials that were somewhat challenging to

use, and unfortunately this can mean that a manufacturer decided not

to release the product into the market.

We need challenging

materials, we need to work with or find ways around the limitations

and allow more people to experiment with exciting developments like

this foaming PLA.

I'm please that

ColorFabb have not only developed this material, but they have

decided to release it. It's not a totally 'simple' material to use,

and it will challenge some machines and users. But my message to all

materials developers and filament manufacturers is to let more of

your 'test materials' out for use. Even if that's with a lot of

warnings, 'alpha or beta status' or as E3D have done in recent years,

marked challenging materials with a 'here be dragons' labels.

Thanks for making this

a reality ColorFabb – I'm looking forward to seeing many more

materials like this. For me this is one of the materials I have been

waiting for since I started 3D printing.

That's all for now, I hope you enjoyed the (rather long) Part 1 Blog post about this material.

Edit* - Looks like I just got this blog post finished in time - ColorFabb have just announced on Twitter the release date and details for this material - find out more here - *Edit

See you next time, and if you have a new and interesting 3D printing material you want me to take a look at, do get in contact.

Rich.

Please join me on Twitter @RichRap3D if you want to discuss more about 3D printing.