So the Plan with the Z stage is now to use M8 Rod and make some Delrin Nuts for it to move up and down.

I will change over to M10 Trapezoidal leadscrews if this arrangement actually works.

Delrin Bar stock and M8 rods.

Not bad for a first stab at it? - Delrin seems easy to machine on the Lathe, much easier than Aluminium.

I don't need it to look pretty as it's going inside the Z framework.

Drill out a 6mm hole so I can hand-tap the M8 Thread.

Needs to be parted and cleaned up.

Hand Tapped and ready for ramming into the 30mm x 60mm Framework.

They line up with 10mm Holes drilled through the frame so the M8 rod can run up and down.

The Rectangular nature of the centre hole digs into the Delrin and stops it turning around.

M8 Rods cut to size and an 8mm Clamp and washer is used to translate the load onto the bearing.

This mount allows the bearing to rotate and fixes movement.

Seems to work well.

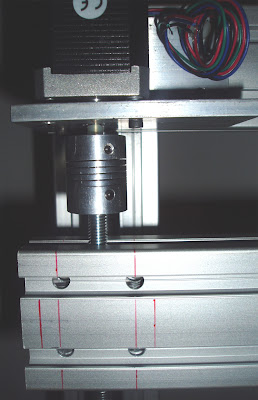

I has a small problem with my Flexible motor couplings. They were 6.35mm and the shafts of a NEMA17 motor are 5mm, so I used a section of 6mm Nylon tube and heated it in a kettle for 2 mins then forced it onto the motor shafts, giving a very snug fit on the coupling.

NEMA 17 Motor (one at each end)

Then Flexible Coupling.

M8 Rod

and Delrin nut inside the Frame Mount for the X Axis.

So the updated RepStrap V2.0 Machine now looks like this.

I need to make the Ballscrew mounts tomorrow, so more updates shortly.

Rich.

Hi

ReplyDeleteWhat bore size PTFE sleeving are you using in the hot end.

Hi Ian

ReplyDeleteIt's 4mm outer and 2mm inner for the 1.75mm filament

6mm outer and 4mm inner for the 3.2mm filament

Rich