Rostock !

Hello and welcome to the Rostock build, it's take a while to get this one documented, I blame that on having way too much fun with my printers and development at the moment, I'll try to be a little quicker on future projects.

The Rostock 3D printer was originally developed by Johann C. Rocholl and is now quite well established in RepRap terms, it's over a year old and has had many different spin-off's and variants by other users and developers. Even Johann has a new design (Kossel Wiki here) based on the openbeam Aluminium construction.

I rather liked the simplicity of the original design, and while I thought about making an aluminium T-slot design around the time SeeMeCNC were doing their very impressive development, I settled on just a few small changes for my Rostock build.

The Rostock has a Delta configuration (Stewart platform) rather than the more common Cartesian coordinate system used by most other RepRap's. The main difference with a Delta based system is that motion on the vertical Z axis is achieved by driving all three positional motors together, this is due to the fact they are in a triangular configuration.

I rather liked the simplicity of the original design, and while I thought about making an aluminium T-slot design around the time SeeMeCNC were doing their very impressive development, I settled on just a few small changes for my Rostock build.

The Rostock has a Delta configuration (Stewart platform) rather than the more common Cartesian coordinate system used by most other RepRap's. The main difference with a Delta based system is that motion on the vertical Z axis is achieved by driving all three positional motors together, this is due to the fact they are in a triangular configuration.

The main downside is that you need twice the machine height as vertical print area due to the way all the push-rods are required to be moved vertically to position the nozzle in X and Y directions.

The mechanical set-up looks complicated, but Rostock has less components than a 'normal' RepRap printer.

It's a very efficient and compact positioning system using only three motors, all able to be driven at high speed by belts or even with 'Spectra' fishing line.

Building it up -

This is a overview video of my Rostock build, you can also see it on YouTube in HD here

Building it up -

First print out a set of plastic parts from Johann's Github Archive -

Next time I take this printer apart, I'm going to replace the LM8UU's with these nice printed ones by Propsfactory printed in Nylon 618.

You will also need some 12mm Plywood or similar material for the base, and you can use the same for the top, I used 6mm Clear Polycarbonate sheet as I will be adding further rigidity with some aluminium T-slot.

The Plywood plate and top dimensions can be found here - Many thanks Culain

The universal joints are a little tricky to print and can be done with a 0.5mm nozzle, but they work better printed with a 0.4mm nozzle.

The rod ends are designed to have either carbon fiber fiberglass, aluminium tube or wooden rods inserted into them. - I opted for hardwood dowels glued into place, make sure they are all the same length.

As with most RepRap machines many of the key parts are 3D printed. The push-rods can be fully printed if you prefer, Johann's diagonal rods.

The main Carriage and universal joints are assembled like this, using M3 bolts, washers and captive nuts (hidden on the inside of each joint arm).

They should be tight and still rotate freely, but not spin.

Carriage arms are added - I used black heat shrink on the rods to keep them smooth.

You need three vertical rod carriages, these carry 2 x 8mm (LM8UU) Linear bearings or bushings.

Linear bearings are very noisy on this printer (I used them) I would strongly recommend thinking about using printed PLA/Nylon bushings or any other type of brass or plastic bushing rather than linear bearings.

Image by Propsfactory

You should just have a small clearance on the vertical carriage ends, you may need to use quite thin zip ties for the LM8UU/Bushings or they can catch on the joints.

The finished carriage its then attached to the bushings/LM8uu's with zip ties.

Three motor mounts, for Nema17 motors.

The Plywood plate and top dimensions can be found here - Many thanks Culain

One of my small modifications was to add feet to this printer, it serves to raise the platform so both the electronics and power supply can be fitted neatly under the ply platform. It also provides a stable base.

These Rostock feet can be found here, 3 different versions and my Sketchup file if you need it.

Nema 17 motors can be attached and if you want the optional bearing support can also be added.

I fitted the bearing support as I had originally intended to make the printer run with Spectra line, I dropped this early on as I wanted to get the system up and running, but after using Spectra line with the Tantillus printer, I will take another look at implementing it on Rostock.

Spectra line idler - a simple brass bushing and two printed rings.

I had the whole Rostock carriage working with Spectra line, but I was not happy with my motors, they were under-powered Unipolar types (I'll go into that in a separate post) so for now I switched back to using normal 2.5mm Belts.

In the original Rostock design, more 12mm Ply wood panels were used for the upright supports, I replaced them with lightweight 20mm x 40mm Extruded aluminium uprights (800mm tall).

Using aluminium sections makes it easy to attach extruders, filament spools and other things to the machine and gives it a clean look compared to more sheets of ply wood.

Electronics -

I'm sticking to my slightly unconventional 5 point mounting system for the Heated bed, this always works so well for me. I added PET tape for insulation and to help further protect the PCB tracking. The solid copper side will be used for the print surface.

Cooking mesh as the insulator, Aluminium foil and card as the heat shield / reflector

Wiring and thermistor - then mount it to the Ply wood platform with spacer washers, as required.

I'm using the Arduino Mega and RAMPS 1.4 board for this build, it's the last one I have, so for future projects the RUMBA or Megatronics boards will be used, or maybe something else...

Three hall effect sensors are fitted to the tops of each axis, these are ideal for a machine like Rostock as the home position is all the way at the top. Upon printing, the head moves down to the print surface. Hall effect sensors use small magnets fitted on the carriage to be triggered, you can tune them with a on-board trim pot, so micro-fine accuracy for the first layer can be obtained, and they repeat position detection perfectly.

All the electronics and power supply are mounted on a cut up plastic chopping board for ease of assembly.

I'm using a 20A 12V supply.

All connected up and still easy to access if required.

This is a modified Greg's extruder, for Bowden drive and 1.75mm filament.

I have still not yet found (or designed) anything better than the Geared Greg's extruder with Herringbone gears. All direct drive extruders I have tried to date, are in my opinion, a waste of time.

It can be mounted on the T-slot at an angle suitable for the bowden tube and the very tall Z travel.

Files for this Bodwen Geared Extruder can be found here - The Sketchup file is also added - and it also works well for many other printers, not just Rostock.

Hot End -

I'm using a J-Head Mk-V-BV for the hot-end, 0.4mm nozzle and 1.75mm filament guide From Hotends.com - they totally rock, and handle abuse and constant running without getting upset.

I originally tried a J-head clone, but had a rather poor experience with that, the supplier has since made further modifications and I have a modified one to try out, I'm planning a hot-end comparison mega-test at some point soon. A recent explosion of new designs are popping up all over the place. - keep an eye out for that.

For the J-head mount I originally downloaded this version by Piit79 shown below,

After printing one, I decide not to use it, but to make some modifications, shown below.

My original modifications added more stability to the mount and also added M4 bolts for the Groove mount found on most J-heads.

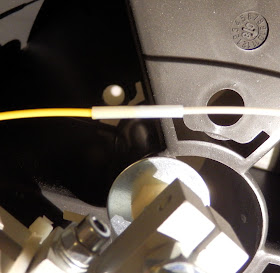

The revised design worked, but I didn't like the bowden clamp method, so I removed it and replaced with a screw in Pneumatic fitting ,the same as the Extruder. This always works really well and even allows the tube to rotate if required.

The heat shield shown was a nice idea but I didn't end up using it as it restricted air flow to the PEEK block and I found that the extra vertical M3 bolts were not required.

You can get the J-head extruder mount files here - Sketchup file also included if you want to change anything.

Next it was wired and ready to calibrate and test.

I also added a standard 4 line LCD and SD slot to the RAMPS electronics, you can see below.

As you can see from the above Rostock is tall, but uses a smaller amount of desk space than a typical RepRap 3D printer.

Sitting on the Rostock print bed above is a Tantillus 3D printer for size comparison, it can print some really big things!

I made a matching Glow in the Dark enclosure for the LCD and SD card, modified and based on the nice model by Chri here

It mounts on the short section of 20mm T-slot at the front of the machine and sits at a 45 degree angle - nice and easy to use and see.

Did I mention this Rostock glows!

This Rostock printer is completely made in Glowbug Yellow PLA from Faberdashery -

It Glow in the Dark for that little bit extra special printing experience.

The firmware used on Rostock is a modified version of Marlin, Johann removed the Cartesian engine and replaced it with the Delta coordinate system, so for anyone familiar with Marlin it's simple to get up and running.

You can get the Firmware for Rostock and Kossel on Johann's Github page here

If you have not made too many changes to the standard sized Rostock, it's almost all set-up for you, but as always check the config.h carefully, especially for electronics type, end-stop orientation and type and not forgetting your extruder calibration.

One really great thing about this printer is the fact the carriage moves out of the way before a print and you have a Z offset defined in the firmware. for me this was set at 395mm with a 4mm heated Glass bed, but it's great when you need to print on other surfaces. All you need to do it adjust this offset for any difference in print surface thickness. No further adjustments of end-stops needed after initial setup. In four months I have not adjusted them once.

When I want to print with Nylon, I just clip a 2mm plate of Tufnol onto the Glass bed and adjust the Z offset to 393mm.

First print-

My first print was the Bud vase by MakeAlot, this was super sized to cover a good proportion of the print surface and allowing a good check the vertical build area.

Hairspray on heated mirror-glass - works well.

After fine calibration with the hall effect end-stop sensors, I had a flat and level bed. I have also started using Hair-spray with PLA on glass, it works well and is not quite as powerful as watered down PVA glue, so part release is much easier.

I used 10% infill with the Bud vase, and concentric infill allows you to quickly see if you have any Z axis alignment issues.

I was rather stunned how well Rostock does vertical alignment, it's easily the best printer for speed, accuracy and layer alignment that I have built to-date.

I had some minor issues on layer-change caused by retraction speed and length, but after increasing that from 3mm to 4mm and speeding up the extruder to 40mm/Sec in firmware Rostock was printing well.

Another very small print and 0.25mm layers, shows how good the layer alignment is with Rostock. (Small version of the Tiki statues, see below)

Printing Big Stuff-

Next stop was to print some things I have always wanted to try at a large scale.

Before Rostock I was limited to about 145mm height on the big MendelMAX, now I have almost 400mm of Z build height.

The obvious next choice being any of the the amazing Math Art designs by Asher Nahmias ( AKA - @Dizingof)

*easy is relative, almost anything with 3D printing can be a total nightmare if you don't have things set-up well :)

You can print it hollow, but the base section needs at least 5% support the the internal floor.

Next up was another model by Dizingof, this time the rather interesting Water Lilly Vase -

Really nice detail on this design and again easy to FFF 3D print.

The finished print is just under 280mm High

The Trinocular 3pot vase is nice, but I over estimated the use of infill (15%) on this one and it ended up weighing over 400gramms - and I ran out of Yellow plastic right at the end of the build -

So here is a quick tip for when you get to the end of a spool during a print -

For 1.75mm Filament it's quite hard to manually join, but if you use a small section of 3mm Outer and 2mm Inner diameters PTFE tube, you can join it very easily.

First cut the tail and of the existing filament being used in your machine (yellow above) and slide on the short tube section, then have your new filament end ready (pearl white) and melt the end of the first filament (yellow) slide up the tube so half of the now melted yellow end is in the tube, and slide in your second filament.

Heat the outside of the tube again, just a little and push both filaments together, then pull slightly apart and roll the tube in your fingers.

You will end up with a nice strong join that should have no problems going through your extruder, even in a bowden configuration.

The small tube should not cause a problem, it will usually just be at the front of your extruder, just remember to remove the tube section the next time you change filament or change colour.

This was collected from about 750g (~400M) of loose 1.75mm filament, it had been sat around for a few weeks on a open spool, but it's amazing how much dust and fluff can be trapped in your material, just imagine that clogging up your extruder and hot-end.

Tornado Vase design my Mere, considerably bigger than the original.

Another favorite - The Teethy Tiki model by Perry Engel (AKA - Cerberus333) - do check out the other designs by Perry, they are really nice and great fun too.

Still not maxing out my build height - this print is 340mm tall (13.5")

The Heart Vase design by JelleAtProtospace printed big, (Also makes a great sweet bowl when half printed)

It also has another name on Thingiveres... I'll leave that to your imagination.

Many thanks to Johann C Rocholl for designing the most innovative and inspiring RepRap 3D Art printer of 2012. Hopefully in 2013 will see some equally wonderful open source designs.

I have already started designing my own version of a 3D Delta printer, as I was so impressed with this one.

I originally posted this Rostock 3D printer build over on the 3D printing industry Website, a rather good place for all news and views relating to 3D printing, do check it out, I'm sure you will find it very interesting.

In other 3D news -

I made up an Eggbot printer for Easter printing with my kids, they love it - here's a quick shot of very first prints -

It's just about dialled in now - getting some nice results from this little machine -

I'll do a post about how to build one up at some point, but if you can't wait, I printed out this one from Glasswalker, and do a search on eggbot for designs to inspire and print out onto your choice of Egg shaped object. Happy Eggster.

I'll have another post very soon with some very interesting printing effects...

Thanks for reading, happy printing.

I made up an Eggbot printer for Easter printing with my kids, they love it - here's a quick shot of very first prints -

I'll have another post very soon with some very interesting printing effects...

Thanks for reading, happy printing.

Rich.

Awesome write up Rich! You've inspired me to get back to work on my delta once I have the time to breath again. Calling it the most accurate printer is quite the statement coming from you. I became discouraged because of the noise, crappy direct drive extruder, bad pneumatic fittings that slipped, and seemingly poorer quality on larger prints. You've proven the quality, noise could be solved by different bushings, and the extruder and fittings can be replaced. Can't wait to hear about the Tantalus as well!

ReplyDeleteThat's great news, Delta's are rather good when all set-up, I'm most impressed.

DeleteI'll have the Tantilus post done soon. That's another great little machine.

Let me know how you get on with the Delta build.

Excellent blog as always Rich, any chance of a link to where you purchased your pneumatic fittings?

ReplyDeleteThanks, and no problem, they are 4mm Straight Adapter 1/8" BSPT fittings - these have a tapper thread so they cut well into warmed up PLA or ABS - you can also use BSP types with an o-ring they are just a little harder to screw in.

DeleteThey were from Engineersmate - great service - http://www.engineersmate.com/

Great blog and great looking prints

ReplyDeleteAny chance of a squint at your 'config.h' and 'config_adv.h' files as I am still configuring and my rostock has roughly the same spec.

Many thanks

Great job!!

ReplyDeleteAre you going to post all the additions/changes to the boards?

I know you already have the extended feet on Thingiverse.

Rich, great blog post!, its always nice to read you.

ReplyDeleteYou have convinced me to make a rockstock!

Is it a bad idea to use a normal gregs extruder with this printer?, i want to use all the things that i have laying around and if i go bowden i would need to buy the tube and fittings (while relatively cheap, my boss, aka "wife" has cutted 3d printing funds to a minimum, Argentina's economy sucks, specially on these days).

With a Rostock (delta) printer you are better off using a bowden extruder.

DeleteThis is because any mass added to the head reduces your possible speed. The ultimaker is the same way since it's head moves in both X & Y direction as did the original Darwin model.

And of course you want to be able to go as fast as possible since the build time is one of the primary disadvantages of FFF (FDM) printing.

That is so cool!! Who knew that a printer was capable of doing that?! Just looking at that gives me some awesome ideas that I might have!

ReplyDeletethanks for another awesome post.

ReplyDelete>I was rather stunned how well Rostock does vertical alignment, it's easily the best printer for speed, accuracy and layer alignment that I have built to-date.

this is indeed quite a statement. adding in the smaller footprint, huge height, simplicity and symmetry, is there a reason why one _wouldn't_ want to build a rostock instead of a mendel-like design?

I would not want to run a Delta with a extruder on the carriage, so Delta's are normally Bowden based. That has some limitations, but most can be now accommodated in Slicers and firmware.

DeleteOther than that aspect, no I don't see why you could not do everything and more with a delta printer that you can do with a Mendel-like design.

And a delta could still be faster is almost every respect.

If I could make it as quiet as my Mendel, I may only need a Delta :)

Hi Rich,

ReplyDeleteexcellent post! very very useful

I'd appreciate if you can tell me what belt & pulley configuration you have in your Rostock (appear to be a T2.5)...

Best regards

Yes, it was the standard 2.5mm belt and pulley configuration used on all my other printer's - and used on most printers - you could use 2mm pitch - that seems to be more popular in the US for some reason.

DeleteHello Rich,

ReplyDeleteI am following you on Twitter and read aslo with great interest this Rostock on your blog.

I am very impressed by your build and your results !!

Thanks for this detailed explanations

I have read for a long time about reprap and after reading hre, would like to start to build one like you did.

1)Do you think it's a good idea as a first reprap? (I have DIY skills, and know about electronics)

2)would you agree to provide a bom ( if you have one of course) that you used for your rostock ?

3)Can you please tell me its total cost ?

Best regards,

Jean-Claude from France

Hello Jean-Claude,

ReplyDeleteI'm following you on twitter too, so DM me if you want to talk more.

1) - Yes it's a great machine to build, and no reason not to build it as a first machine.

2) - I improvised with a few things, so it's 90% the same as a standard Rostock, but with a few things that I had at hand - like wooden rods, PLY and plastic, extra parts from Thingiverse, I'm sure I could work out a BOM, but most of the links are already in the BLog post, just let me know if you get stuck finding anything.

3)- Cost, I'm not exactly sure, as I had many of the parts already, but it should cost less than a Prusa Mendel to build as it has fewer parts.

Also you can save cost, by using what you can find, like wood for the base and top - wood for the supports instead of the Alu extrusion and almost any set of RepRap electronics.

Best Regards,

Rich.

Hi Rich,

ReplyDeleteI like what you have done to enhance the original design. After a friend turned me onto the whole reprap 3D printer world I had to have one and decided on a Rostock delta. I am currently waiting to see what it will cost me to have all the plastic printed on a $45,000 abs machine. A friend used to have one and sold it but still has access to it and he will get a discount on the job to boot.

I was wondering if you have extended the length of the 8mm smooth rods for extra height on the machine, it looks like it's taller than Johann's original.

The other thing I see is another 3 braces or brackets that sit just above the motor mounts, the ones that have the large pully gear for the belts. I haven't seen that part in the original BOM and have not seen them on the original Rostock ... can you elaborate ?

Journey

PS> wish me luck ... I'm guessing the abs print job will be expensive so may end up buying a kit, do you make and sell kits ?

HI Rich,

ReplyDeleteGot another Q fer ya. I was putting together all my stl files I need for that expensive print job I mentioned above and ... I noticed a huge difference in the length of the rods between the diagonal version and the rods from the original Rostock-master file (git). The git/master version is only a little under 13 cm. I wonder what the hell is up with that ??? That's like for a half size version but the rest of it is the same as the June 29th 2012 latest release files which has the rods at about 26 cm including the ends.

How long are your rods with end joints attached ?

And again, did you use longer stainless 8mm rods to increase the overall height of the machine ?

Hi Rich,

ReplyDeleteI used your great Rostock as an example to build my own Rostock. I almost finished up the assembly and everything`s working fine so far. My only challenge is to attach the timing belt (GT2 pulleys and GT2 belt) to the carriages. Could you give any advice on how to attach the belt to the carriages and how to find the perfect length?

Thank you so much

Tom

Truly amazing article Rich, keep up the good work :) I'm writing a blog on 3d-printing, may I 'repost' the article in order to spread word? You can find the site at http://www.absplastic.eu

ReplyDeleteMany thanks, cheers!

Ramon

Pretty good post. I just stumbled upon your blog and wanted to say that I have really enjoyed reading your blog post.

ReplyDeletePrinter Support

Yeah, i agree that it was a nice blog and it would be one of the best printer i saw till this time. Thanks for sharing this amazing information.

ReplyDeleteprinting sydney

Wow, I really like the big print area. how big is it exactly? And how much $/€ did you spent to built this machine?

ReplyDeleteI am building my first 3D printer and have decided to use your Rostock Delta design. Where can I get the PCB for the Hall Effect Sensors?

ReplyDeleteHow to write a resume - Creating a resume is a skill which needs practice and better understanding about your determination. Be 100% sure that spending another couple of minutes to learn how to make a resume will bring a ...

ReplyDeletehi rich

ReplyDeleteive been researching 3d printers for a while and i keep coming back to your blog, as there is a lot of money to be made in 3d printers with all the kick starters and indigogo projects, its getting to the stage where its almost equal open source and corporatist ventures, which makes it a little more difficult to find out about the real "brass tacks" of the device, so thank you Rich for sharing so much with the world, most days where im researching its not uncommon to have 50 tabs on firefo open!

i have a few questions regarding the details of a printer,

is there an optimum resolution or i should say maximum resolution one can achieve with these filament type printers? will it get much more accurate?

i love the delta design would this be a fair project for a first timer or should a gantry xyz type machine be better first?

is it really that modular i.e buy some hardware some electronics put it together and download firmware and slicer software and print? if it is like this that pretty amazing!!

im thinking of getting the new 4-PI board would anyone recommend this? as i feel i would like to future proof the machine for a short while it seemed sensible to buy a newer style with more features.

filament, why 1.75mm? why not 1mm whats the crucial .75 mean? i feel rather silly to ask but i feel there must be a reason mathematically why these thing are the way they are, after all this is a mathematical/geometry interpreter right?

I live in New Zealand, i moved here from the uk and im now feeling the pinch of inaccessibility of materials here (its x3 the cost) so i would like to do as much research as possible without making financial mistakes with parts, so if anyone can put me in the right direction with good advice maybe, that would be great.

again thanks

simon rose

special effect prosthetics and design

http://srosefx.wix.com/simonrosefx#!